Excavator Hydraulic Pump and Engine Parts: Key Components for Efficient Operation

Excavator Hydraulic Pump and Engine Parts: Key Components for Efficient Operation

Blog Article

Excavators are powerful machines widely used in construction, mining, and other heavy-duty applications. To ensure these machines operate at their peak efficiency, two crucial elements come into play: the excavator hydraulic pump and excavator engine parts. In this article, we will explore the roles of these components, their importance, and how they contribute to the overall performance of an excavator.

Excavator Hydraulic Pump: The Power Behind Fluid Movement

Theexcavator hydraulic pump is a fundamental component that powers the hydraulic system of the machine. It converts mechanical energy from the engine into hydraulic energy, creating the necessary pressure to move fluid throughout the system. This hydraulic fluid is responsible for driving various parts of the excavator, such as the boom, arm, and bucket.

Types of Hydraulic Pumps in Excavators

There are different types of hydraulic pumps commonly used in excavators, each with its specific function and advantages:

Gear Pumps: Known for their simplicity and durability, gear pumps are often used in smaller or mid-sized excavators. They are reliable and capable of providing steady flow rates, making them ideal for consistent operations.

Piston Pumps: Piston pumps are highly efficient and capable of generating high-pressure levels, making them suitable for heavy-duty applications. They are commonly found in larger excavators that require precise control and powerful movement.

Vane Pumps: Vane pumps are typically used in systems that require medium pressure and smooth operation. They provide a consistent flow of hydraulic fluid, which is essential for applications that demand accuracy and stability.

Importance of a Well-Maintained Hydraulic Pump

A properly functioning hydraulic pump is critical for the efficiency and longevity of an excavator. Regular maintenance and timely replacements are necessary to prevent issues like fluid leaks, pressure drops, or reduced machine performance. When the hydraulic pump operates at optimal levels, it ensures the excavator's movements are smooth, responsive, and powerful.

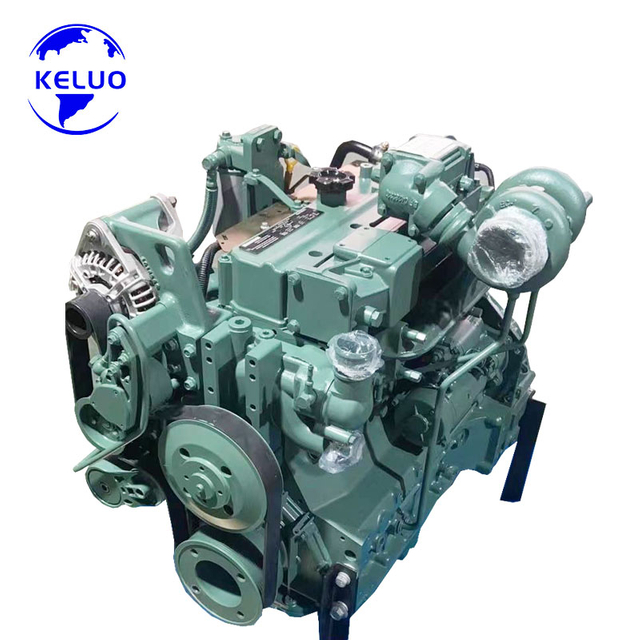

Excavator Engine Parts: The Heart of the Machine

The engine is the powerhouse of the excavator, converting fuel into the mechanical energy required to drive the machine's various functions. Excavator engine partsinclude a wide range of components that work together to ensure the engine runs smoothly and efficiently. These parts are crucial for maintaining the performance, fuel efficiency, and reliability of the excavator.

Key Engine Parts in an Excavator

Cylinder Block and Pistons: The cylinder block houses the pistons, which play a vital role in the internal combustion process. The movement of the pistons within the cylinders is what generates power for the machine.

Fuel Injection System: The fuel injection system is responsible for delivering the right amount of fuel into the engine cylinders. A precise fuel injection process is essential for achieving optimal engine performance and fuel efficiency.

Turbocharger: Many modern excavators are equipped with turbochargers to enhance engine power and efficiency. A turbocharger compresses the air entering the engine, allowing more fuel to be burned and generating more power without increasing the engine's size.

Cooling System: The cooling system, including radiators, fans, and coolants, helps regulate the engine's temperature to prevent overheating. Proper cooling is crucial for the engine's durability and overall performance.

Exhaust System: The exhaust system expels gases produced during the combustion process, helping to reduce emissions and noise levels. An efficient exhaust system also contributes to the engine's power output.

Maintenance of Excavator Engine Parts

Maintaining the engine parts in top condition is essential for preventing breakdowns and extending the life of the excavator. Regular inspections, timely replacements of worn-out components, and using high-quality engine oil and fuel can significantly improve the engine's efficiency and reliability.

The Relationship Between the Hydraulic Pump and Engine Parts

The hydraulic pump and engine parts of an excavator are interdependent, working together to deliver the machine's required performance. The engine provides the mechanical power that drives the hydraulic pump, which then creates the hydraulic pressure needed for the excavator's functions. A well-maintained engine ensures that the hydraulic pump receives a consistent power supply, leading to efficient fluid movement and smoother machine operations.

Benefits of Optimal Coordination

Enhanced Machine Efficiency: Proper synchronization between the hydraulic pump and engine parts leads to faster response times and improved control of the excavator's movements.

Reduced Fuel Consumption: A well-tuned engine and hydraulic system can reduce fuel consumption, making the excavator more cost-effective to operate.

Increased Lifespan: Regular maintenance of both the hydraulic pump and engine components helps prevent premature wear, reducing the risk of breakdowns and extending the lifespan of the excavator.

Conclusion

The excavator hydraulic pump and excavator engine parts are critical components that play a central role in the machine's performance and reliability. Together, they power the excavator's movements, ensuring it operates efficiently in demanding environments. Regular maintenance and timely replacement of these parts are essential for keeping the excavator in top working condition, reducing downtime, and maximizing productivity on the job site. Investing in quality hydraulic and engine components is key to ensuring the excavator's long-term efficiency and durability.

Check this video:

Report this page